One of the core innovations of the ISO-Plane is its fully autonomous loading and unloading system, operated directly from the cockpit by the flight crew, without any external ground equipment.

Cockpit-Controlled Operations

All loading and unloading sequences are commanded by the pilot from the cockpit. Assisted by sensors, cameras, and automated control laws, the system allows precise positioning, lifting, and securing of cargo while maintaining full situational awareness.

The aircraft can perform these operations independently on unprepared sites, standard runways, or logistics platforms, significantly reducing ground infrastructure requirements.

Supported Cargo Configurations

The ISO-Plane loading system is designed to handle multiple standardized payload configurations:

- One 20-foot ISO container placed directly on the ground

- One 20-foot ISO container loaded from a standard truck trailer

- Two 10-foot ISO containers handled simultaneously

- One 20-foot ISO palletized load

- Various loads

This flexibility allows operators to adapt the aircraft to a wide range of logistics missions without modifying the airframe.

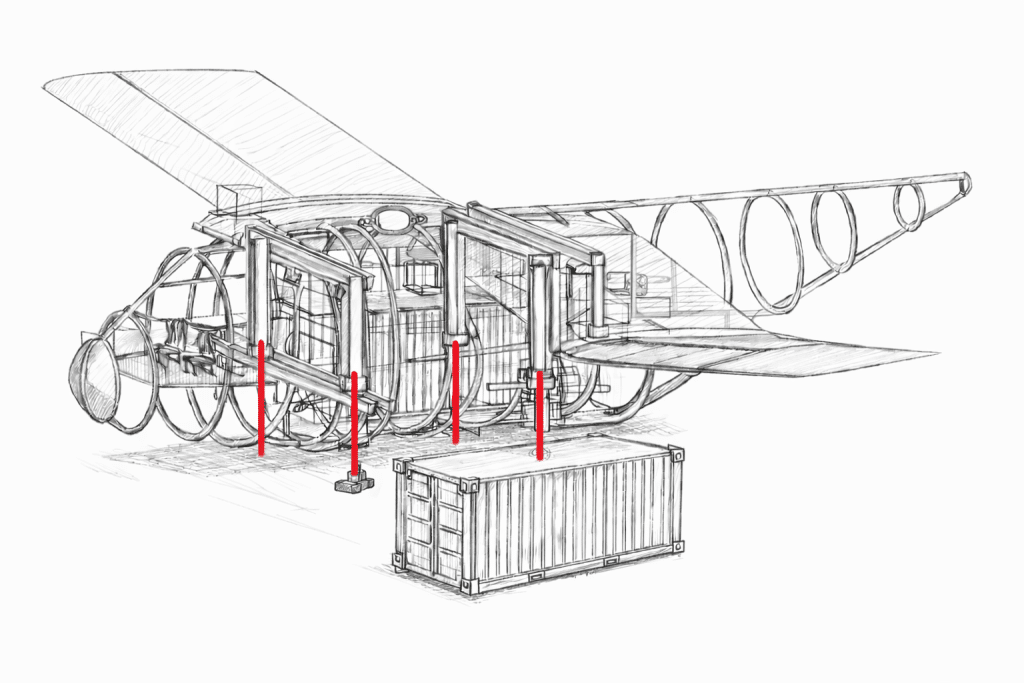

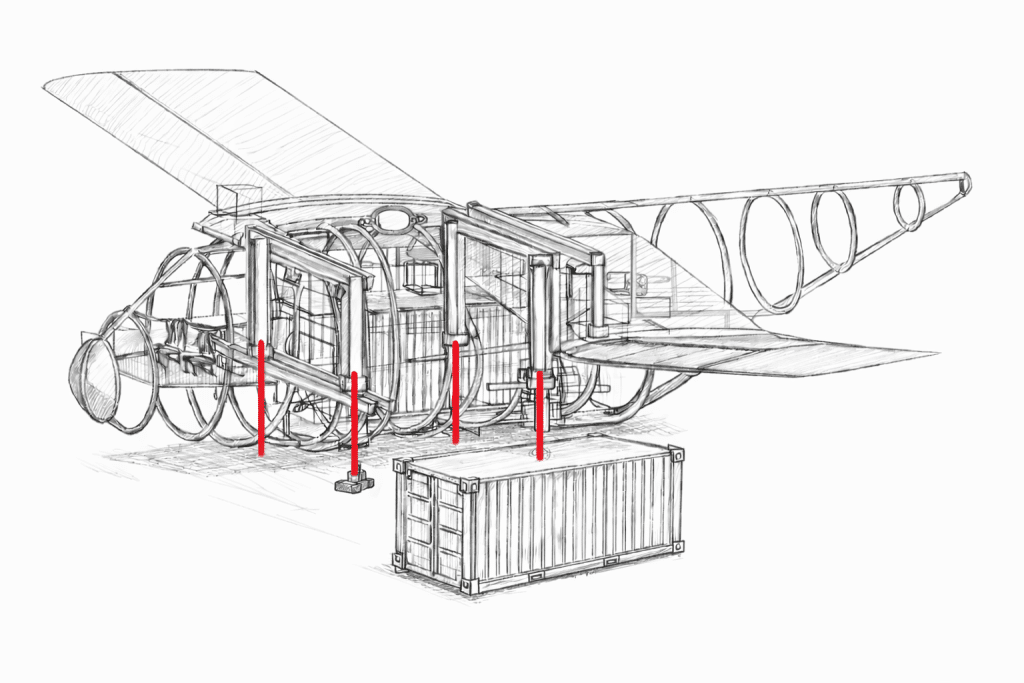

Telescopic Robotic Arms

The aircraft is equipped with four telescopic robotic arms, integrated into the cargo bay structure. Each arm is designed to engage the lower ISO corner fittings of containers or compatible pallets.

During loading or unloading, the arms deploy vertically and laterally to align with the cargo corners, lock mechanically using ISO-compatible interfaces, and lift the payload in a synchronized manner to ensure stability and load balance.

Ground and Truck Loading

For ground operations, the aircraft aligns itself above the container using visual and positional references. The robotic arms descend to capture the container corners, lift the load, and retract it into the cargo bay.

When loading from a truck, the truck positions the container beneath the aircraft. The ISO-Plane performs fine positioning using its powered landing gear before engaging the container and lifting it directly from the trailer.

Ventral Cargo Access

A dedicated ventral cargo door system provides direct access to ground-level loads. The multi-panel opening sequence is synchronized with the loading arms to maximize clearance while preserving fuselage structural integrity and pressurization capability.

Adaptive Cargo Floor

When the payload is not a container, a removable and retractable cargo floor can be installed inside the cargo bay. This floor transforms the container bay into a conventional cargo hold suitable for palletized freight or mission-specific equipment.

The floor system interfaces with the aircraft structure and can be installed or removed depending on mission requirements, preserving the aircraft’s versatility.

Safety, Redundancy, and Control

The loading system incorporates multiple safety layers, including synchronized motion control, load monitoring, and fault detection. In the event of an anomaly, the system can be stopped, reversed, or switched to backup modes.

Manual override and assisted modes remain available to the crew at all times, ensuring safe operations under all conditions.

The autonomous loading system is developed as part of the open ISO-Plane architecture and continues to evolve through academic and industrial collaboration.